2021-12-16

STEP 1-INSPIRATION

Tubular tri-proof is inspired by our lives, the circle closely related to our lives. The circle is one of the most common and practical life elements in our lives. Compared with the square, the circle has more flexibility and convenience. Therefore, Tubular tri-proof has a lot more flexibility than traditional tri-proof lamps. For example, it can be used in special fields such as car washes, food processing plants, chemical plants, etc. The lamps used in these fields not only need to have high waterproof The requirements of grade, impact resistance, and corrosion resistance also need to be easy to clean, and Tubular is a very good choice.

STEP 2-RAW MATERIAL

First of all, we will screen out high-quality materials through strict layers of raw materials (for example: stainless steel is made of food-grade 316 stainless steel) to meet higher requirements for fire resistance, corrosion resistance, and impact resistance.

STEP 3-PHOTOMETRY TEST

Use professional equipment to conduct rigorous optical testing to ensure that each lamp can reach a light-emitting angle of >120°, which guarantees the comfort and uniformity of Tubular's light-emitting.

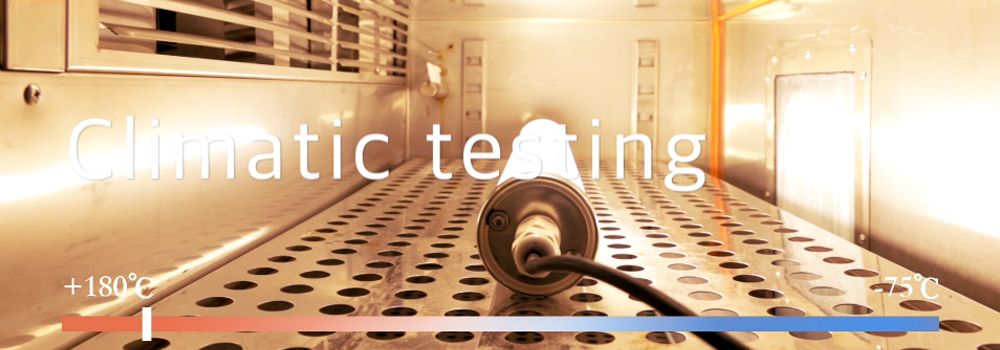

STEP 4-CLIMATIC TEST

Simulate the normal use limit in extreme weather, and carry out +180℃~-75℃ extreme temperature test to ensure that Tubular can be used normally under extreme weather conditions.

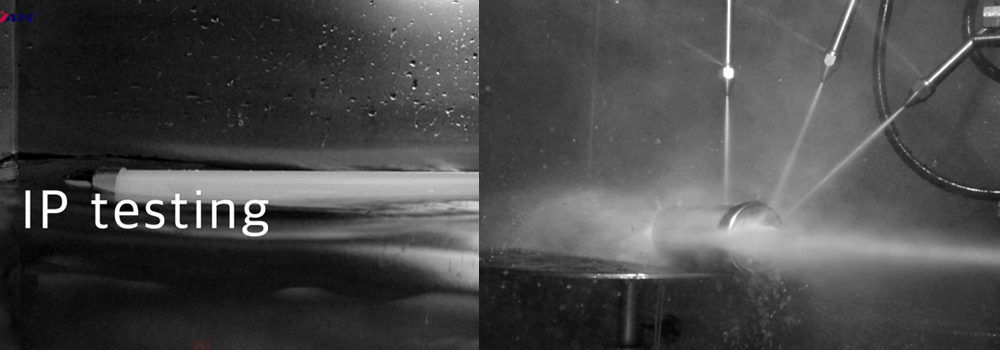

STEP 5-IP TEST

IP69K waterproof rating test: Capable of withstanding the thermal steam wash test defined in EN 60529 and DIN 40050-9. This provides protection against water pressures of 100 bar (1450 psi) and temperature of 80°C. The pressure is applied directly to the sensor at progressive angles of 30° (0°, 30°, 60° and 90°) for 30s at each angle for a total of 120s (2 minutes) to prevent water ingress.

STEP 6-IK TEST

IK10 impact level test: The protection level of the luminaires against the penetration of dust, solid matter and dampness is in accordance with the UNE 20324-93 and the EN 60529 standards, a classification awarded for protection levels provided for the coverings.

STEP 7-CORROSION TEST

Corrosion resistance tests are carried out to simulate the environment of special application fields (food processing plants, chemical plants, car washes, etc.). This test makes the application environment of Tubular more diverse.

STEP 8-ELECTRONIC TEST

The electronic stability test ensures that each electronic performance of the lamp can reach excellent quality (no flicker, anti-interference), and minimizes electronic radiation and is free from other electronic interference.

STEP 9-GLOW WIRE TEST

Simulate the thermal stress caused by hot components or overloaded resistance heat sources or ignition sources in a short time, and use simulation technology to assess the fire hazard to ensure the flame retardancy of the lamps.

STEP 10-SALT MIST SPRAY TEST

For use in heavy salt places such as coastal areas or salt processing plants, Tubular needs to perform a Salt Mist Spray Test to ensure that the tubular can be used normally in a heavy salt environment and meet the requirements for salt corrosion prevention.

STEP 11-PRODUCTION ASSEMBLY

Tubular is produced and assembled by advanced automated equipment and skilled workers.

Step 12-Aging Test

The aging test for up to 8 hours can fully detect the lamp dead rate, heat dissipation, luminous efficiency stability, etc., to ensure that the tubular can be used normally and continuously under the maximum effect.

Step 13-Package

After a series of compliance tests, Tubular finally reached the packaging stage.

STEP 14-SHIPPING

After everything is ready, our Tubular officially embarked on its new journey and shipped to all parts of the world to let more people know ERVAN LED Tubular.

STEP 15-FAMILY

LED Tubular is of course composed of a large, systematic and complete family member.

STEP 16-APPLICATION

Tubular has a wide range of applications: food processing plants, car washes, oil pollution treatment plants, chemical plants, wine cellars, warehouses, railway stations, shopping malls and other fields

Product Links: https://www.ervan.cn/download/tubular.html

Video link: https://www.youtube.com/watch?v=IIZUfoNLAkE&t=9s