2021-08-06

With the continuous development of the LED industry, people's requirements for light are getting higher and higher. In the past, the glare value of lamps and lanterns used in commercial office buildings has been paid attention to, but now more and more European countries pay attention to the comfortable vision of industrial workplaces (warehouses, production halls, etc.). According to EN12464-1, high glare lighting makes workers’ eyes fatigue faster, causing unsafe operation and low efficiency. However, the biggest technical difficulty in realizing the low glare value of industrial lamps is that the glare value is directly proportional to the luminous flux, which means that the high power and high lumens used in the industry will increase the glare value. This is a technical difficulty that is difficult to break through for the entire LED industry.

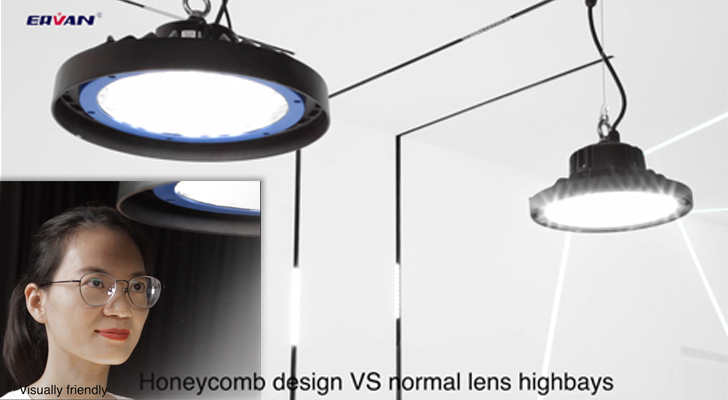

After 5 years of research on the honeycomb cup design, ERVAN has found a balance between large luminous flux and low glare in optics by combining optical components with products, which has solved the pain points that everyone has faced for a long time. For this research result, ERVAN applied for a Global Patent (No 004670651-0001) to protect the customer's market. The honeycomb cup low glare high bay lamp is an ideal solution for industrial applications requiring UGR <22. Low glare lighting provides workers with a more comfortable visual working environment, thereby making the operation safer and more efficient.

In the past, traditional high bay lights had to add a reflector in order to achieve low glare effects. The addition of this reflector would have three major disadvantages:

1. The cost of the reflector is high, and the value of a reflector is 10-15 US dollars.

2. Increase the transportation cost and warehouse space. The volume of the reflector is larger than the lamp itself, which undoubtedly doubles the transportation cost. The large volume also takes up a lot of space for the warehouse storage.

3. Increase the installation cost. The lamp body and the reflector are independent. If you want to combine the lamp body and the reflector, you have to add the installation cost of labor cost. Nowadays, the labor cost is very expensive, which will be A lot of expense.

ERVAN's honeycomb high bay light uses a unique integrated design combining honeycomb cup and lamp body, which effectively solves the need to use reflectors to achieve low glare, thereby greatly reducing the cost of buying reflectors, transportation and warehouse costs , And the cost of manual installation.

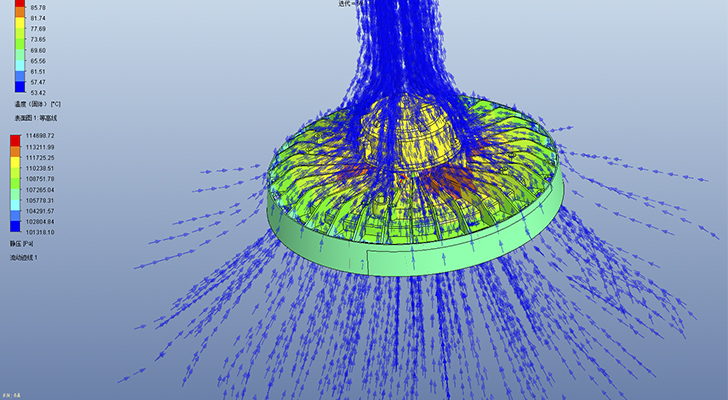

In terms of the design structure, ERVAN high bay lights also carry out product heat dissipation design, forming a good heat convection. Long-term high temperature will reduce the lumen value and shorten the life, thereby increasing the cost. The heat convection design solves the problem of scientific heat convection for high-power industrial and mining lamps, and the use is more stable and lasting.

ERVAN has obtained quite a lot of good customer feedback on the results of low glare lamps and lanterns all over the world. His optics, structure, appearance, and cost are all very big advantages. If you have other better ideas or needs, we can also tailor ODM for you to make your product an exclusive one. If you want to know more, you can watch our product links and video links, or contact our sales staff to answer more professional knowledge for you.

Product Links: http://www.ervan.cn/download/low_glare/Low_GlareH29_196.html##

Video link: https://www.youtube.com/watch?v=QYB_fhfZSIY